The FAB Hardware¶

The FAB is based on cheap, readily available hardware (an Arduino microcontroller and widely-available pressure-sensors) and the key mechanical components are 3D printed and can be assembled by lab technicians. Ready-assembled units are also be available to buy.

More details, including circuit diagrams, schematics, and CAD files sufficient to enable 3d-printing and assembly of a device, will be available soon under a permissive open source license.

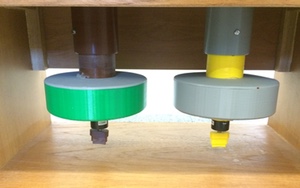

- The piston

- The key mechanical component is a 3D-printed piston which contains 2kg of ballast and a linear motor to drive the probe which makes contact with the participants finger. As the linear motor drives the probe downwards and makes contact with the finger the piston is lifted from a rest position, but the maximum weight which can be applied to the probe remains 2kg [1].

- Arduino microcontroller and sensors

- An arduino microcontroller is used to drive the linear actuators and capture data from two load cells mounted within the pistons (between the probe and the motor). These data are fed to a controlling PC via the Firmata serial protocol.

| [1] | Where 1kg = 9.8 mN |